Ageing & Obsolescence

The Problem

With thousands of obsolete items and many more items under threat, obsolescence is a significant and growing issue that faces the UK nuclear industry. Critical Components and Single Point Vulnerabilities may be given attention but any obsolete item; whether a component or a system, can cause significant problems when spares become unavailable.

The AMS Approach

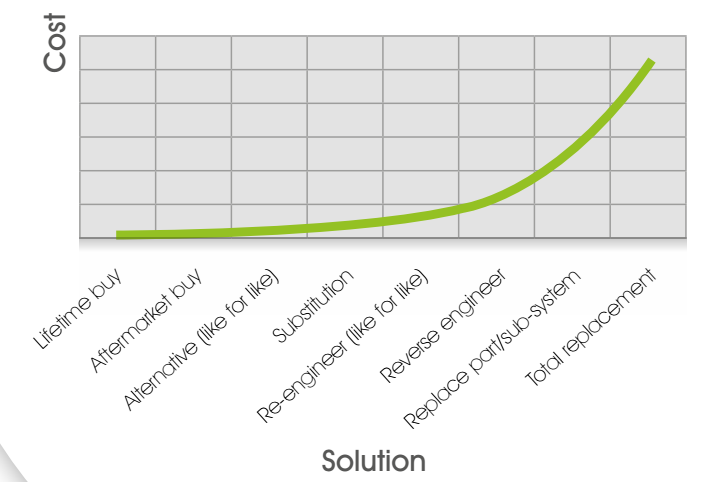

AMS recognises the relationship between the possible solutions available and the associated cost implications. AMS has the knowledge and experience to, not only engineer total system or sub-system replacements, but also to carry out Item Equivalency Evaluations (IEE) and Fit Form & Function comparisons which enable the lower cost solutions to be considered first.

Working with Appropriate Rigour (WAR); AMS applies the principles of BS EN 62402:2007 Obsolescence Management to its own solutions and where appropriate can apply client specific guidelines to the design process conducting and incorporating OPEX analysis for safety critical system design.

AMS Obsolescence Capabilities

AMS’s obsolescence specific capabilities include the following:

- Internal SQEP C&I engineering resource

- Properly managed supply chain of supplementary design and manufacturing services

- Component, Sub-System and System design capabilities

- Reverse Engineering of PCBs

- TTL/CMOS/Analogue expertise

- Plant knowledge / systems knowledge

- Item Equivalency Evaluation (IEE) Authors

Related

Documentation

13331

EC&I Obsolescence Solutions Brochure

Related

Case Studies

Replacement CCR Hardwire Fire Alarm System

EDF Energy – Hinkley Point B

AMS provided a detailed design for a replacement hard wired fire alarm system for Hinkley Point B Nuclear Power Station.

Superheater Overpressure Instrumentation Replacement

EDF Energy – Dungeness B

AMS was tasked to find a suitable modern replacement for the two signal isolators and the power supply based upon an item equivalency evaluation.