Pioneering Safety in Fusion Research

The University of Liverpool, in collaboration with the National Physical Laboratory (NPL), is at the forefront of fusion materials research. As part of the SBRI Fusion Innovation (Phase 2) programme, the University required a robust, laboratory-scale test rig to explore the performance of newly developed organic materials under industrial conditions.

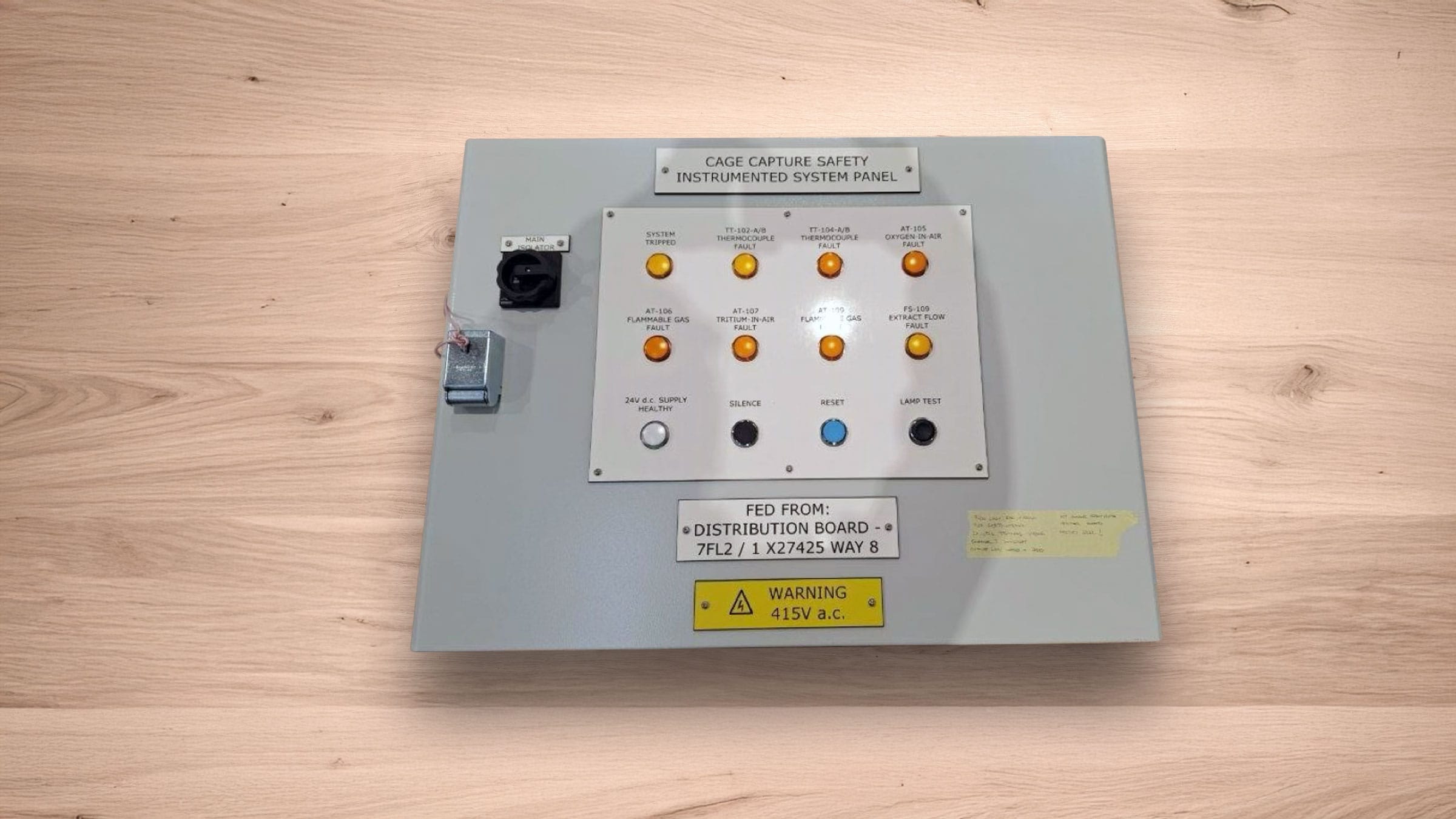

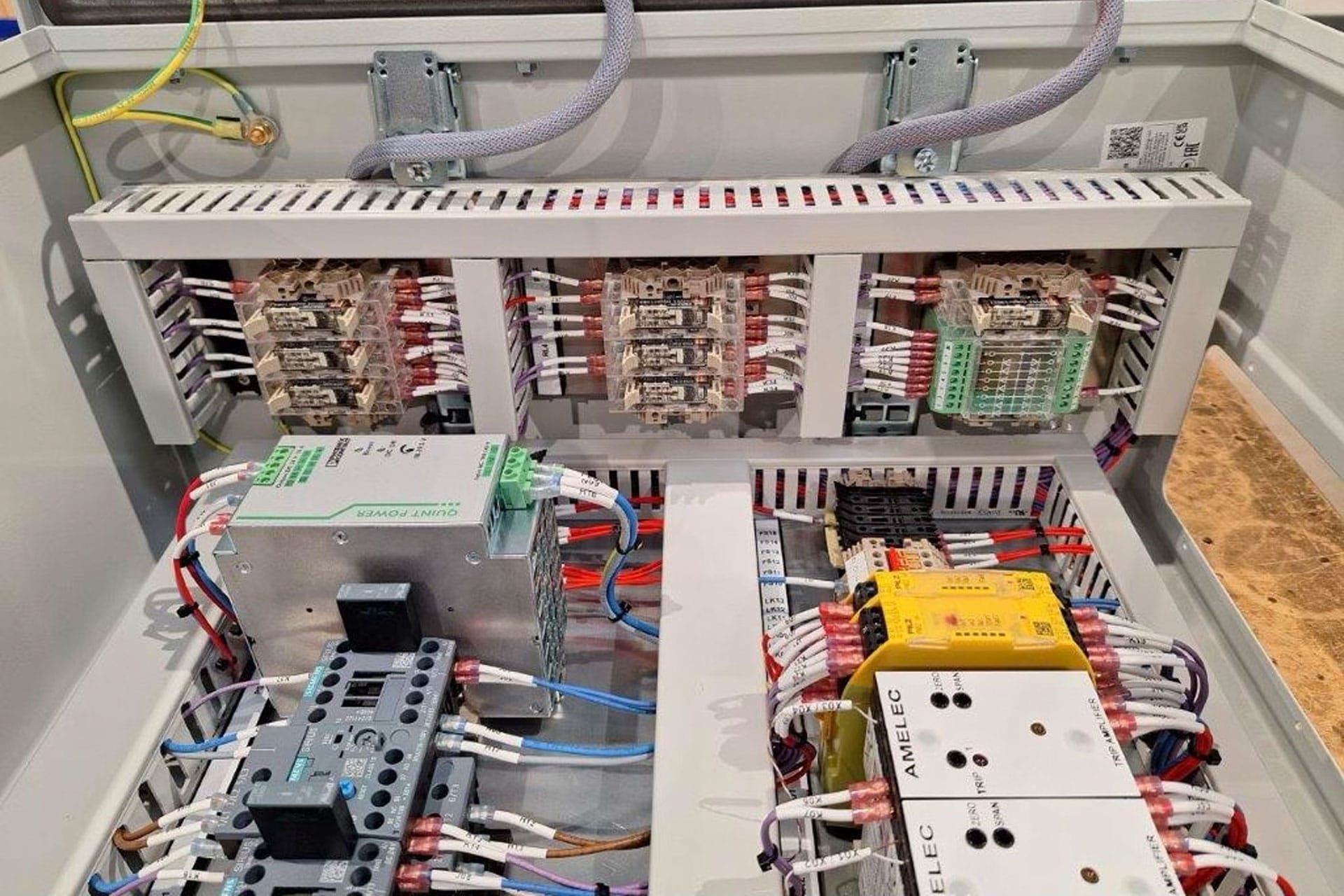

AMS was entrusted to design, build and deliver the project’s Safety Instrumented System (SIS) panel, a safety-critical component ensuring the rig could operate reliably under tightly controlled parameters. The system needed to protect both people and equipment — automatically shutting down the rig within one second of detecting unsafe conditions. With a proven reputation for delivering dependable, safety-critical EC&I systems on time and right first time, AMS approached the project with technical precision and commitment to accountable delivery.

The test rig’s operation relied on precise and safe control of complex systems, including pumps, cryostats and containment systems. Any interruption or loss of control could risk valuable data, equipment and time. To enable research continuity and uphold the highest standards of safety, the University needed a solution that could not only meet the technical specification but also instil complete confidence in the system’s reliability.