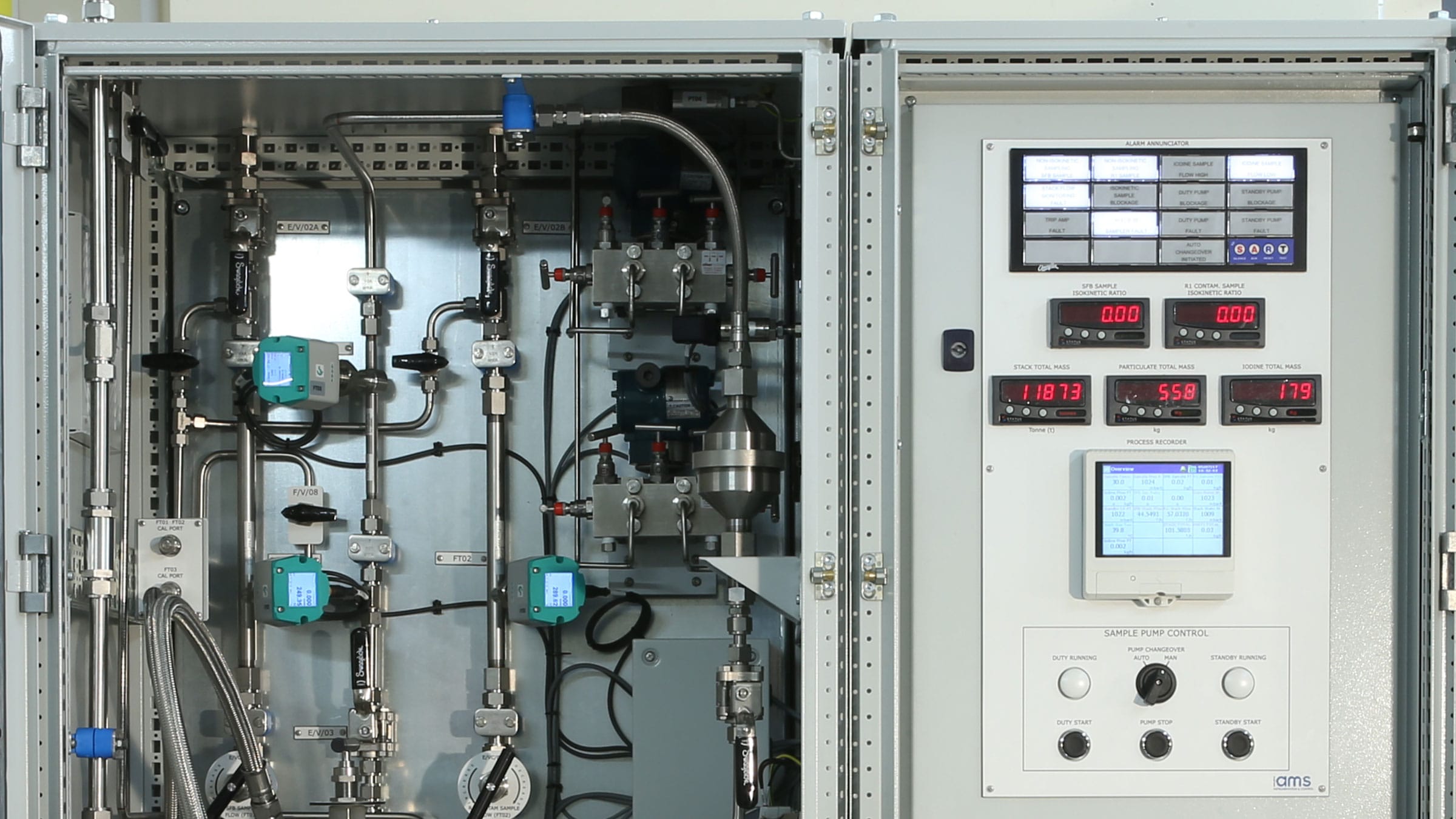

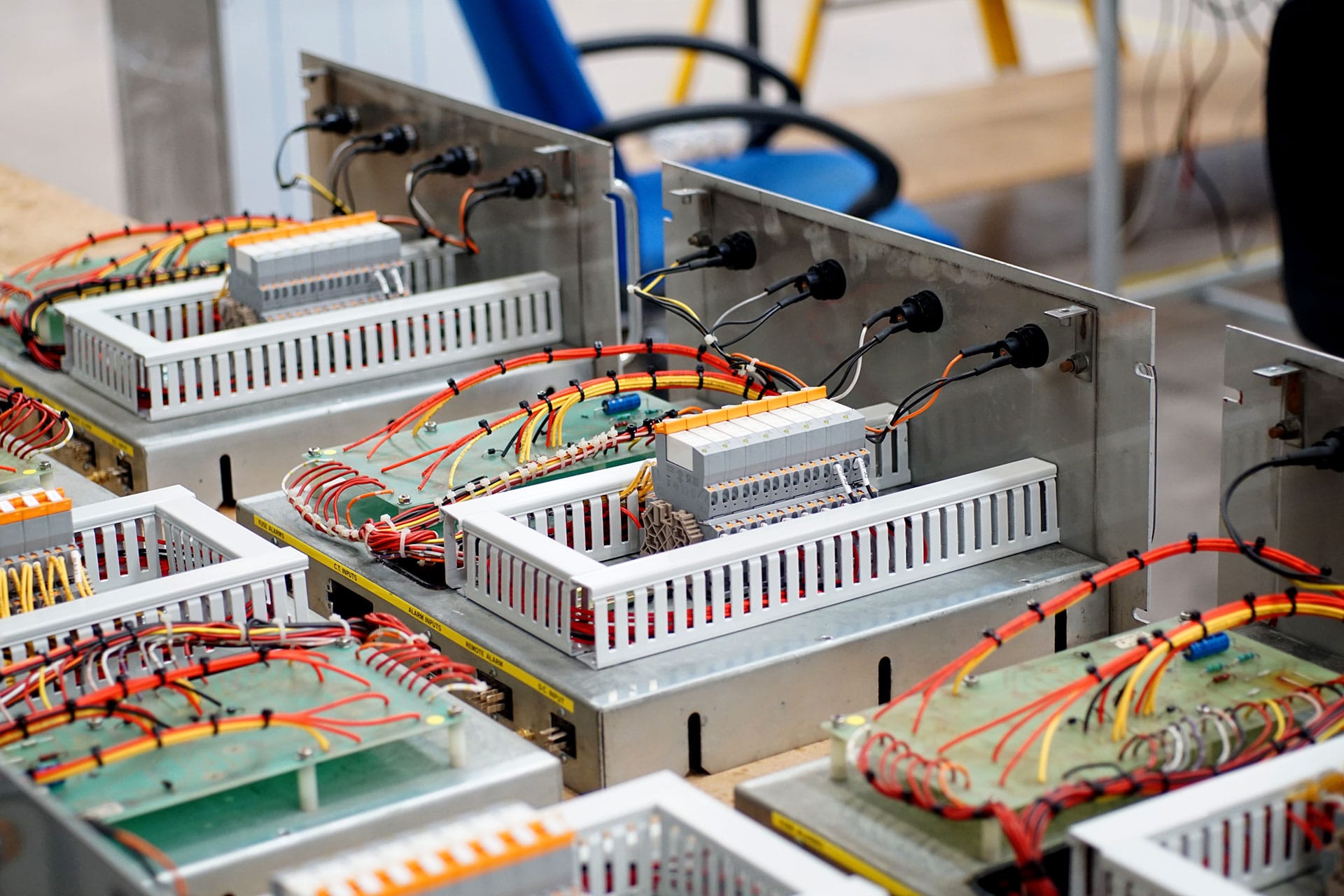

AMS Nuclear delivers bespoke EC&I systems across the full project lifecycle, from initial feasibility studies through to installation and commissioning. Following a proven V-model approach, we provide either complete turnkey solutions or discrete elements working collaboratively with clients and partners. Our vendor-independent position ensures we specify the best technical and commercial solution for your application, whether that’s process instrumentation, PLCs, pneumatic systems, relay logic, or alarm management systems for nuclear licensed sites.

End-to-End Capabilities

AMS Nuclear delivers integrated Electrical, Control & Instrumentation (EC&I) systems from concept to commissioning, backed by a proven track record across the entire nuclear project lifecycle. For over 25 years we have provided the full EC&I solution – consulting, designing, qualifying, building and testing safety-critical systems for new builds, operational reactors, decommissioning projects and defence. Our vendor-independent approach ensures each solution is technically optimal, practical, and delivered right-first-time. Every project is executed by our Suitably Qualified and Experienced Personnel (SQEP) team, following rigorous quality processes and a robust nuclear safety culture so that safety remains the top priority. We consistently deliver on time and on budget, as evidenced by hundreds of successful projects to date.

SQEP Expertise Across Applications

Our consultancy services are led by SQEP experts adept at navigating the UK nuclear sector’s regulatory landscape. We provide detailed design substantiation, technical input to safety cases, equipment qualification programs and stringent standards-compliance support to ensure every solution meets its regulatory requirements. With over a decade of framework experience on EDF Energy’s reactor fleet and with more recent involvement at Hinkley Point C new build, we understand how to satisfy nuclear industry procedures and quality standards. We foster a well-developed nuclear safety culture with security-cleared personnel, reflecting a proactive, accountable approach to quality and safety. Clients trust us to deliver clear, dependable guidance that keeps their projects on track in highly regulated environments.